RFID

Sensors with convincing cost effectiveness

With RFID, no direct “visual contact” between the read-write unit and transponder is necessary. Information from the transponder is received by means of electromagnetic waves. As a result, these systems can be used practically and reliably under even the most adverse conditions.

Advantages for you

- No visual contact required between the write/read unit and the transponder: The radio waves penetrate various materials such as wood, cardboard or plastic depending on the frequency range

- Integrable:

RFID transponders can be integrated into the product or the transport medium. - Robust and reliable:

Thanks to their robust properties, RFID systems also function reliably in harsh environments. - Data storage during the production process:

When using writable transponders in the production process, production and quality data can be stored directly on the transponders during the process.

Know-How

What is an RFID system?

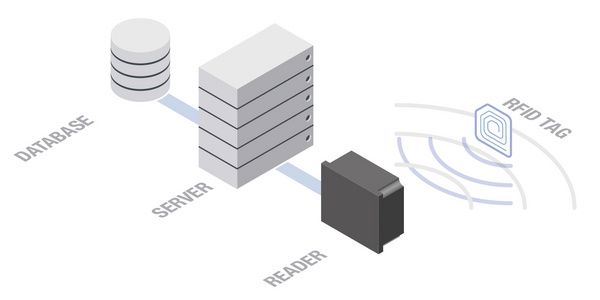

RFID, which stands for Radio Frequency Identification, is a technology used to identify and locate objects using radio waves. An RFID system consists of at least one RFID transponder and one write/read unit, which have integrated and/or external antennae.

How does an RFID system work?

Electromagnetic waves are used to transmit the data between the transponder and the write unit or RFID reader. Each RFID transponder consists of one antenna and one microchip. A unique, unchangeable serial number, the Unique ID, is always stored on the microchip. Depending on the type of transponder, other object-related data is also stored on the microchip.

RFID transponders can be active, meaning that they use an integrated power source for data transmission, or passive, meaning that they draw the energy required for data transmission from the electromagnetic field of the RFID reader. RFID systems use low frequencies/LF (125 kHz), high frequencies/HF (13.56 MHz) or ultra-high frequencies/UHF (865 MHz to 928 MHz) for the data transmission. The used frequencies vary depending on operating range, transmission rate and susceptibility to interference.

In which areas can RFID be used?

- Production control

- Access control

- Identification of persons and objects

- Skid, container and pallet identification

- Material flow control in conveyor and storage systems or the automotive industry

What must be considered when selecting an RFID system?

- Read out the UID number and compare it with the database

- How is the write/read cycle activated?

- Continuous mode of the write/read cycle

- Triggering of the write/read cycle

- Is additional transponder data required?

- Interface and protocol to the superior system (industrial Ethernet or serial interface)

- Data retention concept

- Write data (repeatedly) to the transponder

Application

RFID container identification

Requirement:

In the food industry, the containers and, thus, the data carriers are exposed to various cleaning processes and chemicals. To be able to read and, if necessary, store product-related data at every processing point, the data carriers must be especially robust.

Solution:

Thanks to their high degree of protection of up to IP 68/69K, the TFM and TFI transponders are – in combination with the RFM and RFI read/write devices – very well suited for use in the food industry. On the TFM RFID transponders, quality data and process data can be stored during the production process.

RFID skid identification

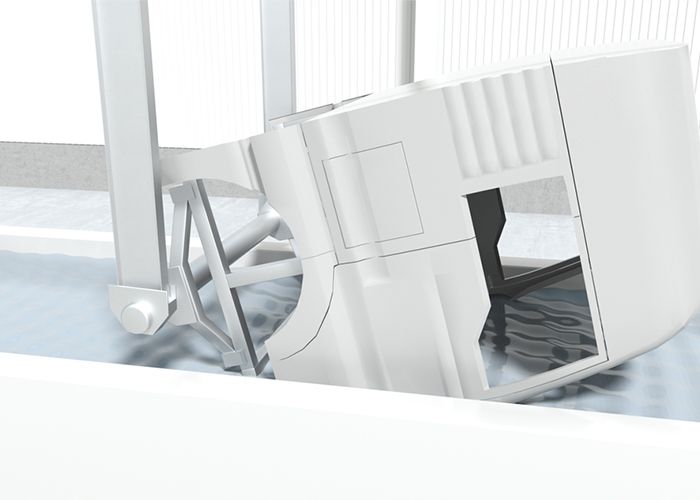

Requirement:

In the automotive industry, data carriers must, to some extent, withstand high temperatures during processes for the surface treatment of body parts. Furthermore, paint particles can prevent visual contact with the data carrier.

Solution:

The RFID waves of the RFM read/write devices can penetrate even layers of paint. The corresponding RFID transponders can withstand temperatures of up to 250 °C.

RFID pallet identification

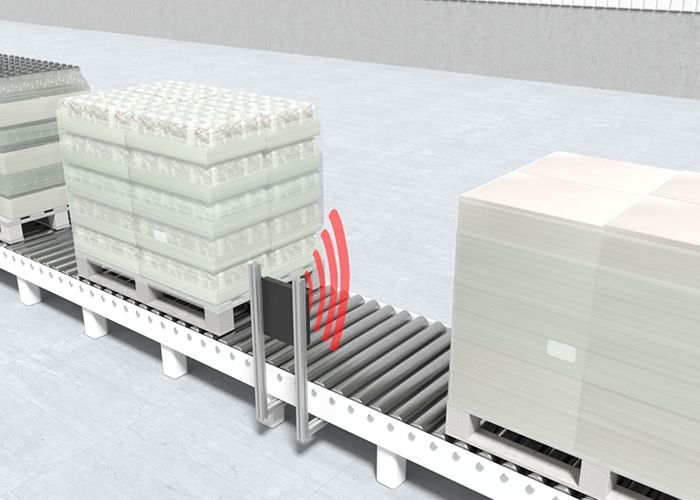

Requirement:

During pallet identification, the data carriers are either on the pallet or on the material that is to be transported. Here, the pallet feet may be soiled or the data carrier may be located under the packaging film. Thus, visual contact between the identification device and data carrier is possible only to a limited extent if at all.

Solution:

With the RFM read/write devices, the data carriers can be read from and written to even without visual contact. Insensitive to dirt, the transponders of the TFM series are available as hard tags or smart labels.