Leuze Contrast sensors

Sensors with convincing cost effectiveness

Contrast sensors detect and compare contrasts very precisely through the use of different light sources such as white light, laser-generated red light or RGB light. The detected contrasts marks are then reported to the process with minimal signal jitter. Through the automatic selection of the right transmitter colors, various color or gray value combinations can be reliably detected. Bar graph indicators offer additional ease in making adjustments during manual setup.

Highlight: KRT 3C

KRT 3C contrast sensor: Our smallest contrast sensor for the packaging industry New contrast sensor for fast and reliable identification of contrast differences in situations with limited installation space

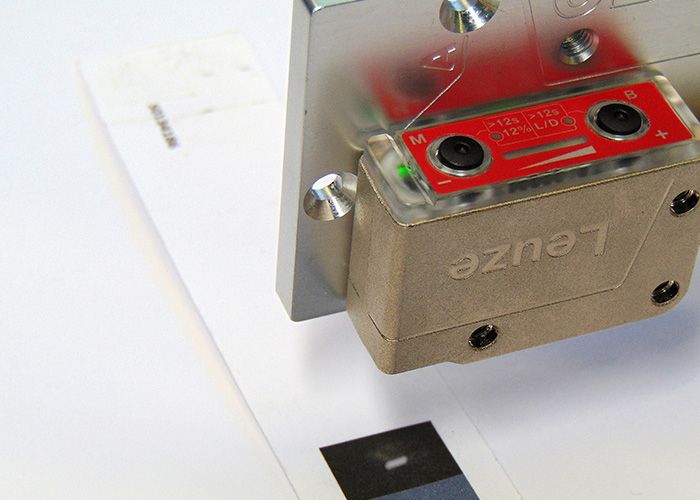

Contrast sensors are developed to detect defined markings on objects during packaging processes. These contrast markers are located on film, bag and blister packaging or on labels. The new compact contrast sensor of the 3C series can be used flexibly with different transmitter colors (RGB light, white light or laser-generated red light) for all common color and gray value combinations. It reliably and precisely detects even slight contrast differences, as well as print marks even on glossy materials.

The sensor is developed for tight installation spaces: With a very compact housing (11 x 32 x 17 mm), it is our smallest contrast sensor and offers a high level of mounting flexibility. The robust plastic housing covers degrees of protection IP67 and IP69K. ECOLAB certification confirms the housing’s resistance against cleaning agents commonly used in the packaging industry. All settings for integration and operation of the sensors as well as for the case of format changes of the products can be easily performed via the IO-Link interface.

Advantages for you

- Flexible thanks to multiple types of light in a single housing: multicolor (red, green or blue light), white light and laser-generated red light

- Reliable detection of even the slightest contrast differences and of print marks even on glossy and highly reflective materials

- Highly precise and reliable identification of contrasts with a short response time of 50 µs (laser: 125 µs) and minimal signal jitter for optimum machine throughput

- High mounting flexibility and easy integration even in tight installation spaces due to a compact and robust housing with a high degree of protection of IP 67 and IP 69K as well as ECOLAB certification

- Multiple teach modes are available for selection, thereby ensuring the appropriate adjustment routine for easy and fast machine commissioning (static or dynamic 2-point teach, static 1-point teach)

- IO-Link for easy integration of additional functions into the machine control, for example easy format changeover due to recipe management, parameterization of the sensor, or locking of the teach button to prevent tampering

Highlights

Highlight: KRT 18B

Extension of the KRT 18B contrast sensor product range by the addition of white-light models with additional teach process Now also in white light – and with static 1-point teach

The task of contrast sensors is to scan an object for a predefined marking which differs in color only slightly from the rest of the background. In many packaging processes, these contrast markers must be reliably detected on film, bag and blister packaging or on labels. The KRT 18B series contrast sensors combine ease-of-use thanks to permanent signal indicators with high performance. Apart from our established models with RGB light source, contrast sensors with white light are now also available and add another teach variant to our product range. They offer fast and intuitive adjustment via potentiometer or teach button, remotely via cable or IO-Link, and feature a unique bar graph indicator that provides permanent feedback about the contrast quality. The highly precise contrast detection is performed with an extremely short response time and minimum signal jitter. The RGB devices are also available with analog output for particularly challenging marker detection applications.

Advantages for you

- Models in multicolor (RGB) or white light (W) offer optimum performance for marker detection on colorfully printed or glossy films

- White light provides greater reliability in the case of contrast markers on glossy surfaces

- Multicolor (RGB) provides better performance with colorfully printed films

- Free selection of adjustment method: intuitively using removable potentiometers, quickly and precisely by means of teach buttons. Also of course remotely through teach via cable or IO-Link

- IO-Link with dual channel: for monitoring, diagnosis, easy changeover in the case of format change

- Three teach levels ensure the perfect adjustment routine for every application

- Static 2-point teach with stationary conveyor belt based on marker and background

- Dynamic 2-point teach with running conveyor belt

- Static 1-point teach detects any contrast markers in front of a homogeneous background

- Permanent signal indication through self-adjusting bar graph on the rear side of the sensor

- Tracking function with threshold tracking for fading contrast markers

- Fine adjustment of the switching threshold through “near-to-marker” teach or EasyTune (T)

- Light spot variants with horizontal or vertical alignment

- Flexible operating range of 13 mm +- 3 mm

- Maximum switching frequencies up to 22 kHz / response time 20 µs

- Small, compact housing made of nickel-plated metal, IP67 and IP69K and ECOLAB

Highlights

Twice as much choice: Contrast sensors in white light and RGB